Depending on what kind of workplace you work in, the chances are there is at least one safety sign placed somewhere on the premises. Because there are tons of things that can go wrong at work. And although a steelworker and an office clerk face different potential dangers at work, both employers have to ensure they’re safe and secure in that environment.

This is where OSHA (the Occupational Safety and Health Administration) and safety inspectors enter the game. And as we’ve seen in Bored Panda’s previous features about OSHA that you can check out here, here and here, their game is on the next level.

As you can suspect, not everything the safety instructors see while on duty puts a smile on their faces. Often, it’s on the contrary. So in order to find out what craziness they have to deal with at workplaces that put safety at the bottom of their priorities, we looked at these two viral threads (this and this) where inspectors and OSHA employees share the worst things they have seen.

Below, we wrapped up the most eyebrow-raising stories, so pull your seat closer.

#1

I was on the Workplace Health and Safety committee. The committee head at the time decided to change a lightbulb. Do you think that she used a step ladder on the sloped surface? Nope, office chair with wheels and nobody to hold it still. So many stupid decisions in that last sentence. Of course she fell, broke her arm, and received work place compensation.The kicker? The light bulb wasn't blown, she was just using the wrong light switch.

Image credits: meri_bassai

#2

Watch 8 tonnes of pipe fall from about 20m because someone was in a rush and used the incorrect rigging.The kicker is everyone there (20-30 people) were totally willing to let it go unreported, except me. I never really did make too many friends after that. Oh well.

Image credits: ski--free

#3

Equipment operator used brake cleaner to remove grease from his hands and arms, then proceeded to light up a cigarette on his way out of the work area... Fairly significant second degree burns on both hands and forearms.

Image credits: daishiknyte

#4

Fire Inspector here, finding a guy using a propane grill inside a building. He was initially pissed off when I told him he couldn’t do that, until I showed him the stratified smoke that was about a foot off the ceiling.

Image credits: escushawn

#5

I didn’t see it personally, but someone smoking & another person eating lunch inside of what was a “high risk” containment during an asbestos abatement.In a high risk you have to be naked under your body suits, shower when you leave, cannot bring anything in or out that hasn’t been washed & you have to wear a full face mask. It’s supposed to be very sterile. These guys had their face masks off inside the containment eating & smoking.

Image credits: vegans-ate-my-cat

#6

I worked in a lab doing cytomegalovirus research. One day we had workers in replacing the lights and one said ‘wow- I always thought those shower things were real!’ Pointing at one of the emergency showers in the lab. These are for heavy duty chemical spills where you run under the shower and pull a handle to decontaminate. Turns out ours were just the shower heads in the ceiling not connected to any water. We used extremely dangerous chemicals every day. We got the showers hooked up pretty quickly after that.

Image credits: Smokeylongred

#7

Guy was a warehouse worker. Qualified to use the forklifts, but this was a special one where the entire cabin lifts up so the forklift worker has better vision. What does the guy do?He gets out 3.5 meters in the air and steps on the pallet to adjust some of the products. The guy faced 0 repercussions. He was a nice guy, but crazy.

Image credits: Roel93

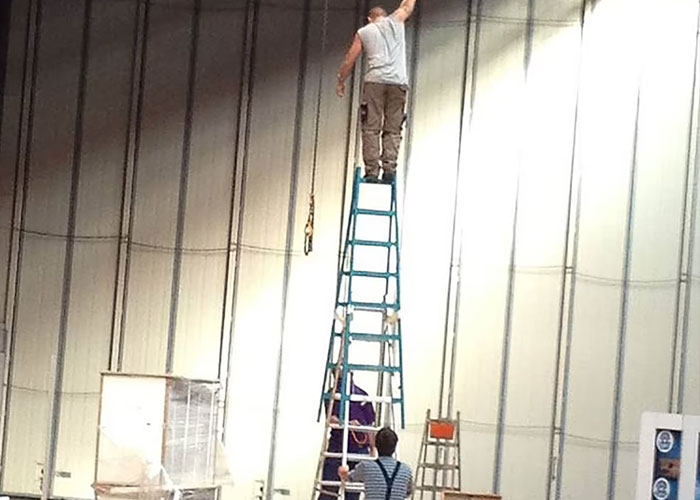

#8

Worked as a Storeman at a retail store. We were having renovations done to the building at the time so there were a lot of construction workers around. One day I walked in on a bunch of Eastern European workers holding a ladder on top of a trolley while one of them climbed it to reach something on the wall (high af ceiling). I flipped my s**t at them and had a go at their foreman as well.

Image credits: snoop_cow_grazeit

#9

Got called to a factory where the workers had to cut metal on large conveyor belts.There were large boxes with built in gloves that you stuck your hands in to operate the press.

So, for safety, workers had on one set of gloves ( that everyone wore on the factory floor because sharp hot metal ) and then stuck their hands in a second pair attached to the belts to reach the materials.

One of the workers felt like this slowed him down so he cut a hole in the safety box to be able to just reach in and adjust the metal to the press... Except, the press came down ON his hand, leaving 4 of his fingers perfectly preserved inside the glove.

They recovered his wedding ring, neatly dangling right above the cut off finger bone.

Image credits: WideFix

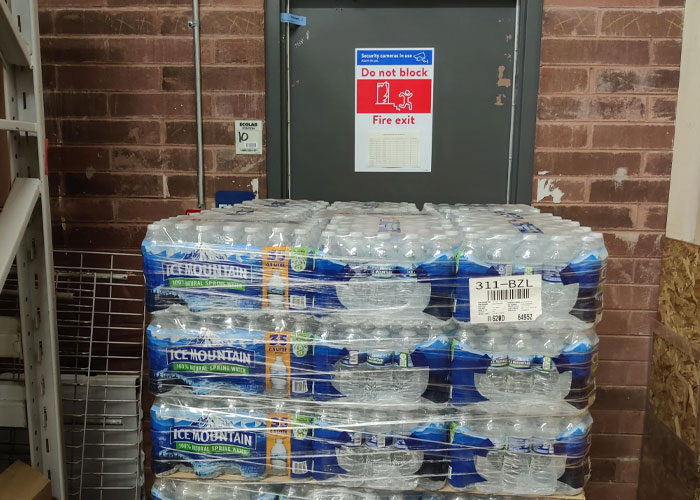

#10

When i used to work at Walmart they use to block FIRE EXITS.they probably still do it yet i dont think OSHA does anything about that.

Image credits: HouseofPain1

#11

I taught skydivers to be tandem instructors. One dropzone bought a new type of tandem rig and faked their training... management had them lie about it to me and another examiner. Chief instructor's excuse: "They're all the same anyway." He had a malfunction caused by his not knowing how the rig worked, and his poor paying first-time passenger had no idea the danger this arrogant prick put him through. The worst thing was the training was free! Seriously, WTF...

Image credits: Base841

#12

Not directly relevant, but I worked for a company where the Risk Management Executive accidentally shot himself in the leg checking to see if the safety was on on a pistol.

Image credits: Curlaub

#13

I've worked for a couple of engineering contractors in the past, my first firm was by far the worst for lack of work ethic and sheer incompetence. OSHA would have a field day with them.One time, our reciprocating saw broke; the foot that held the blade in place was busted, so rather than follow protocol and get another saw, my coworker fastened the blade in place with a plastic wire tie and proceeded to use it.

The same firm worked as contractors for the company my Dad worked for, so he has the best/worst stories about them. On one site, they'd found that sections of a pipeline had been sealed with asbestos gaskets. The boss of my firm (I'll call him Jim) was present on this site, and had to call in a specialist to remove the asbestos.

Jim would never wear safety gear like the other guys, claiming to be "exempt", and so when the specialist turned up in full breathing gear and overalls and tried to do his job, Jim just stood leaning on the pipe in his normal clothes talking to him. My Dad and the others are stood well away from the asbestos at this point, and he shouts out:

"JIM!"

"What?"

"Are you immune?!"

"Immune to what?"

"F*****g asbestos!"

"Ah, I've breathed loads of it in in the power stations, it's all political."

My Dad says that Jim has defied all facets of medical science by staying alive this long.

Image credits: SJB95

#14

I used to work as a safety consultant for an insurance broker. One of our insureds had an employee who was tasked to apply a “Do not enter, compactor starts automatically” sign on a cardboard box compactor. The idiot set the can of spray adhesive on the lip of the compactor, knocked it in, and then jumped in the compactor to get it. Of course it started automatically because it’s a machine that can’t tell idiot from box. He’s lucky some else was walking by and saved his life.Edit: he went into the compactor AFTER sticking the sign to the front of it.

Image credits: mad_wood_scientist

#15

My uncle is a safety inspector and is always going off about dumbasses in the workplace. Same uncle broke his arm in four places trying to clean the gutters of his workplace with a too short ladder on top of an oversized toolbox in wet weather.

Image credits: anon

#16

The ones that make me maddest are the blatant health violations.Mica dust everywhere. No respirators, no exposure assessments, no awareness among anyone at the location of the hazards of mica dust. When asking the EHS folks at the site about it, they just didn't know at all, and I was like "it's your responsibility to know this stuff."

I also audited a site that uses very dangerous pharmaceutical compounds, but had nothing in terms of exposure assessments. They just put it all in a glove box and assumed it was ok. The twist - they had not done any sort of testing on the glove box, or training on cleaning, or validation that the box was actually air tight. There is zero excuse to have no program in place... and employees were symptomatic. Their IH professional was a CIH with a lot of experience so it's not like he didn't know he had to do that stuff... he just hadn't done it.

#17

Guy at my work was collecting a soil sample amd tested it. Right after he finishes the boss says now can you test it all for asbestos when hes been exposed to what he thought was just plain soil for the past few hours.

Image credits: jaybloggs

#18

I have so many I can barely choose. Once I noticed workers welding on a table with their leathers between their waist and the table. Apparently bad wiring in the building was causing the full outlet electrical current to charge the table when the machines were set up so for years people just knew not to touch anything near or on the table during welding work.Once I couldn't stop a place from not welding outside next to their flammable cylinders.

A manager was having an employee scale lime deposits off equipment with essentially CLR and letting it just run free into the storm drain next to him. It literally dyed the pavement for over a year.

Had 2 morons try to get something off a wall in a warehouse. One held the base of a ladder (standard, not A-frame) while the other got to the top wrung and started jumping to reach whatever it was. I shouted to them and the moron holding the base turned to look at me and let go; as you can imagine moron 2 had a quick trip back to the ground.

Image credits: Vealophile

#19

I'm a HSR at my workplace.I recently had management trying to pin a couple of guys on my shift for putting a pallet of product to close to a fire hose.

Ok fair, yeah it's a safety issue.

Only problem was more than half of the fire hoses on site are blocked or inaccessible due to rows of product blocking them.

Poor storage planning on managements behalf, yet 1 pallet near a fire hose is enough cause for a written warning and talks of terminating said employees.

Safe to say when I politely pointed out how many safety hazards and violations that were the fault of the management. They quickly dropped their talks of terminating employees.

Still working on getting those other fire hoses unblocked though.

Like banging your head on a brick wall sometimes I swear.

Image credits: Yenschy

#20

I interned at OSHA. I got to ride around with a former electrical union superintendent and I’m still telling stories. As an intern they honestly let me ask anything. The inspectors were so glad that someone actually respected them and wanted to learn so they just spilled.Personally the worst was a couple dozen guys hung their coats up to cover the hot commercial electrical box they had pig tailed their broken radio directly to. The OSHA inspector saw it and just turned to them and said “do you have a family? Do you ever want to see them again?” Turned out the crew chief had a brand new baby girl at home. He basically cried his face off about how stupid they were and shut it down until they could make it safer. No fines were issued. Even though it could’ve bankrupted all 3 companies on site. Just real talk.

In case you didn’t know that amount of electricity would kill you in the worst way (unable to let go and feeling every single shock) and leave you a pile of dust.

Image credits: briannananers

#21

Employee (with no competency) stole a telehandler. He then proceeded to drive into a fence . When questioned regarding this action he answered that "He was too lazy to walk to the canteen" . 400m away from the work area.

Image credits: anon

#22

I inspect fire sprinklers and I saw someone had a chain going through one to hang a light.

Image credits: beefstewforyou

#23

Not the OSHA guy, but it happened in the plant I was working in. Idiot is told by junior manager to clean the floor after a chemical spill (I don't recall what it was for certain, but we used a LOT of industrial adhesives, so maybe that). Idiot ignores all his safety training, and the entire closet full of cleaning gear, and decides to clean the spill with acetone. And a steel wire brush.It wasn't so much of an explosion as a deep "whumph" sound that sucked most of the air out of the room. He was horribly burned. His clothes melted into his skin. 3rd degree burns covered his body. Incredibly, he was still alive when the Fire and Paramedics got there. He opened his eyes, asked for a cigarette, and died right there on the floor. What did we do? Hosed down the floor, and the line was back up by that afternoon. Quit that job as soon as I was able.

Image credits: Corsair09

#24

Fire alarm/sprinkler leaking onto steel racking for so long it’s rusted. Racking was 6 tier high...Management refused to treat it a hazard.

Image credits: donthatedaplaya

#25

My dad went to his work OHS committee to ask them to mow the patch between the parking lot and the building because the grass had gotten so long that snakes were living in it. The committee decided it was too risky to have someone mow it because there were snakes in the grass and the person mowing might get injured.

Image credits: Mr_A

#26

Not an OSHA employee, but these guys I worked with were undermining a road. Cars were still passing over the dug area. No efforts were made to secure the trench (trench boxes or such), no ladders, a 6' pile of the trench spoils were right on the edge, phone, gas, and power ran nearby but locates weren't done...I'm honestly surprised it didn't collapse, the cars driving overhead shook loose plenty of gravel from the sides of the hole.

Image credits: anon

#27

Not an inspector but did work comp insurance for a bit.I saw this on cctv for evidence

Factory that made foam for mattresses had a machine that would cut up medium sized chunks of foam into smaller ones to put into mattresses. Sort of like a wood chipper.

One guy got tired of putting handfuls at a time (the recommended way) and decided to get a bucket and starts shoveling into the cutter.

When it got stuck from too much foam he used the stick part of a broom to push it thru. This got the broom stuck. He then decides to put both hands in to dislodge the stick and stuck foam.

The machine was still on this whole time.

He somehow manages to get the stick out and the blades start going again.

He amazingly only lost two fingertips and tried to sue his boss.

We settled for 30k...

#28

Former safety rep who specialized in industrial food manufacturing working for the largest food companies. I am now in school for psychology so am interning at a clinic. In my interview I said that was my previous career so they asked me to do their EAP and exit maps. Yet they wont buy the fire extinguisher signs. The thing I repeatedly tell them to do is unlock one of the doors leading to a exit door. They have a storage/file room with one of the emergency exits and you cant walk in the room even if the door is unlocked.

Image credits: Negaface

#29

I'm not a safety inspector but this came to mind.... I am an electrician in Las Vegas. One jobsite I was on was the remodel of the hotel tower at Caesars Palace. We started at the bottom floor and worked our way up the tower one floor a week for a year. It was horrible air conditions, major demolition, massive dust(because the hotel windows in Vegas don't open in order to keep people from jumping out), they rely on exhaust fans to circulate air but don't run the fans for the subhuman construction workers like myself.Then after almost a year, coughing and gagging when we were on the VERY LAST FLOOR(level 44) a team of men showed up in hazmat suits and shut the job down. Appearently all of the sparkly dust we were breathing everyday was almost entirely asbestos. FML

Image credits: humbleprotector

#30

Wasn’t our plant but another plant for our company. We have these huge steel drums that we fill with 100s of pounds of ingredients that go onto an hydraulic lift that lifts and tilts the drum and pours the contents into a kettle.The drum shifts forward a little bit on the lift while all the way up and falls back into place on its way down. The operator was resting his hand on the bottom of the lift while lowering it back down and the drum fell back down on his finger and pretty much turned it into mush.

That’s not the worst part. Afterwards the safety lead was doing a review of the incident and another operator showed the safety lead EXACTLY what happened and smashed his finger in the same manner.

Image credits: vickers24

#31

The safety committee at the state psych hospital I worked at was going building to building, making a surprise inspection. They walked into the Hospital Chapel and found the Chaplain sitting at his desk - getting a blow job by one of the patients who was under his desk.That old f****r should have gone to prison but they let him take early retirement.

Image credits: brutalethyl

#32

I do EHS and watched a bunch of guys using a forklift to literally lift an entire box truck over a fence instead of just pushing it through the gate.They thought I was at lunch. I was not.

#33

Ohhh I can tell you lots of stories. I do manufacturing safety now but was in petroleum before, primarily construction.(1) Was in a DCP midstream plant in Hobbs NM about 50 feet away from a guy joyriding on a forklift who slammed his boom into an overhead pipe, popped a wheelie and ended up with the boom *between* that pipe and another one. When we traced back the pipe he had nearly caused to burst we found it was a 600 PSI fuel gas line. The whole plant would have gone boom.

(2) On the same DCP midstream project, was working a Hydrogen Sulfide disposal well across the street where they were replacing the casing. The well was 35% H2S (1000 parts per million will f*****g kill you in a single breath) and they didn’t want to wear respirators or evacuate and let us check the area under supplied air when alarms went off. We finally told them we were walking off the job if they didn’t straighten their act out - safety personnel legally had to be there and we were the only provider in the area.

(3) At my current employer our CDL driver was backing a trailer up to a dock door at the warehouse, and got out to go inside and make sure he was lined up correctly. He didn’t set the brakes on the truck though and it proceeded to roll freely through the parking lot wiping out people’s cars.

(4) Just recently had two forklift repair technicians use one forklift to pick up another forklift by its overhead guard and then stand under it to do a repair.

#34

I noticed someone on the CCTV cameras riding around in a hover-board while moving a wheelbarrow and was actually impressed until he knocked someone over outside in the pavement.We called him Dangerous Roy and he broke three ribs by jumping onto a rock, slipping and falling onto the cement mixers handle bars. We nearly had to report it to RIDDOR but he left because the pay wasn’t good enough.

Was not mad at all.

#35

While working on a small pipeline project, one guy had a 6-pack of beer under the back seat of his truck. Obviously the beer was warm. We figured we could cool the cans by tipping a propane bottle upside down and spraying them with liquid propane. I guess there is a safety device to prevent this, so we put a hose on the tank and cut the hose. One guy held the cans with his bare hands in the stream of liquid propane on the worksite. Good times.#36

I'm not even an inspector nowhere near but once in culinary class we took a trip to our school cafeteria (I'm still in highschool btw) because my teacher wanted to show us cleanliness. Well foolish of her she took us straight there no warning or heads up to the lunch ladies and it was filthy. Im talking roaches everywhere rat s**t on the floor unknown to us liquids on the floor and then picking their ears and eating the ear wax and going right back to prepping food that would be eaten and hour later by kids. This I the reason the only thing I eat are pb&js because they're in packages and a juice on the side#37

I manage safety for a medium size company in the UK. Best one to date was where I received a phone call informing me a supervisor on the factory floor had damaged their hand in a razor sharp guillotine (approx. 1200mm wide x 1800mm in length). This is an automatic guillotine which cuts material to specified lengths at approximately 5 second intervals. I turned up to find the supervisors hand wrapped in a cloth which had now turned red due to the large amounts of blood. Turns out that some material became stuck in the guillotine preventing the blade from cutting properly , the supervisor without isolating the machine tried to beat the 5 second count and free the obstruction but the guillotine cut right through the palm of his hand.Turns out the blade just missed one of the main arteries in his hand so he was extremely lucky!

#38

Obligatory not OSHA, but I go to a lot of sketchy body shops all day, so I see some unsafe practices. I have two.Once saw a guy using an angle grinder to cut metal. He wasn't wearing any eye protection, and the sparks were flying straight into his face. He wasn't even looking away.

I also once saw a guy using a MIG welder with no welding helmet. Staring straight at what he was working on. Bonus points because he was smoking a cigarette.

#39

I wasn't a WHS officer but I worked in HR. I once had a work over claim come through my desk for an employee who broke their arm pulling a plant out the ground.#40

I once worked for a family owned company that built tow boats and barges. When I asked my friend/boss who got me the job about mesothelioma and why it was so prevalent in the industry he told me, “I’ve been instructed by our lawyer not to answer that question”.Not to mention all of the other things I was told to overlook when I became part of management.

#41

Worked in a warehouse that repaired tools and equipment for erecting wind turbines.There was one beloved program manager that always met schedules early and under budget. All the execs loved him.

But his equipment came back basically disassembled and reassembled with all the safety checks removed so they’d work faster. The way they rigged up the electrical equipment was downright scary.

He’d hire unqualified lifting equipment inspectors for his worksite instead of relying on the corporate guys who took their time and kept documentation on everything.

Stuff like that. Cutting corners whenever he could.

But he got everything done on time so he was a golden goose.

Every time I hear of an accident at a wind farm I wonder if it’s related to that guy.

#42

We just had a guy fall on Friday. He had been complaining about the ladders used for CIP. That they were too small didn't hold enough weight and some were busted. Been complaining for 6 months in every safety evaluation and safety meeting. Dude was taken out in an ambulance. I hope he is alright but I also hope he sues. They don't give a f**k about us here.#43

This is coming from my step brother. He managed a warehouse that had industrial sized rolls of aluminum and other metals. These rolls weighed multiple tons each. They would use an automated crane. They would program each space available, and the crane would place the rolls where they were delegated. My brother tells me about an employee that knew how to work the system with FMLA, this guy was lazy as hell, and knew how to get away with it. It turns out he programed a slot on the top of a stack to be a dead zone, no rolls would go to that one spot. He setup a makeshift bed and would crawl up and take naps. He kept this secret, obviously. If someone had seen this spot was unused and reprogrammed it, the automated crane would have placed a 4 ton roll on top of him while he slept. Some people are wild.#44

I had an employee using a hydraulic shear, 10 tons of cutting force, to down size very hard metals. He got to a piece that was larger than the guard would allow so, of course, he removed it. He went back to sizing the metal of normal thickness. The position of the machine was an L, so his left hand would move the material then actuate the machine with his right. The machine had a deadman's switch so if the handle was released the hold and the shear would pop back up. Long story short he cut his thumb off with 10 tons of force.EDIT: There's more to this story; no touch tools, grandfathered machinery, etc. but the long and short is a guy stuck his hand in a industrial metal scissor and pulled the lever!

#45

Port state Inspector, For me and most of my colleagues its things relating to fire safety, particularly fire doors. The amount of time I've found auto closing doors tied, wedged, weighted or just fixed in the open position is maddening. Fire is the worst thing that can happen on a ship, and these doors have to be able to be closed at any time but people are too f*****g lazy to open a god damn door so they tie them open, and then guess what, time and time again there is a fire and when we do the investigation (assuming there is anything left to investigate) we find a fire door fixed open that's allowed to fire to spreed. People in my industry literally die every year because some f*****g AB or assistant engineer to too f*****g lazy to open a door.Edit: So that's the most maddening, the dumbest would be when a captain tries to stop us from coming on board in the first place. FYI if you are working in the marine industry, never try this, it will end badly for you. One of two things will happen, We will just refuse your ship access and black list you, or we will allow you in and then immediately detain the ship. I remember one captain stood on the gangway and tried to block me and my boss from boarding, he said "this is unreasonable!, we have had no time to clean up or anything and demanding we come back after he had finished cargo operations" Hearty laughs were had and we told him he had however long it was going to take us to walk back up to the harbor master station and walk back down with Royal Police escort and that in the meantime the ship was detained.

#46

I have many years doing safety inspections, I have seen some "fun" things in my time. I have seen industrial fan's cords spliced onto an extension cord with the bare wires exposed and charred and the employer saying it's fine because it still worked. An owner of a nursing home reach into a used and full sharps container to prove that needles were not being recapped. A guy outside of a window on a third story of a house on the edge of a board removing a window pane without any fall protection while his two buddies are inside on the other side of the board holding him up (there is level of trust that I do not have with most folks). Walking up to a house and the owners had made a makeshift driveway out of asbestos siding that they had removed from the building the previous day and seeing kids playing in the area. A compressed gas cylinder filling station would receive old cylinders and they would have to empty them prior to repairing or destroying them, the guy doing this would take them out back and, while holding his breath, would secure them and open up the valves to empty them and then go inside. This worked okay for a while until it didn't and he got dosed with a massive exposure to arsine gas (the company usually didn't deal with this gas but had received from one of their customers for disposal) which almost cause complete renal failure.These are just a few that I can recall that kinda stuck with me. There are lots and lots of run of the mill safety issues that I see all the time but the majority of the time it's ignorance of the law and not malice for most employers.

#47

I seen two Spanish lads grinding a 12" Sched 80 Moly Pipe, only they had no clamp, so one held it at face level, and they had no glasses or face guards, so they were both desperately looking away to avoid sparks in the eyes#48

I do environmental compliance, specifically air pollution control. One day, we received a complaint from a former employee of a company about a whole laundry list of stuff his former employer was doing wrong. That's not super unusual, people get fired or quit on bad terms and call basically every agency they can think of for 'payback'. Anyway, we responded. When we got there, there were a few things that weren't right...but the icing on the cake was that they had this pollution control device that was supposed to be collecting dust from one of their processes. One problem though...all of the dust was on the ground around it. We told them in no uncertain terms that it was unacceptable, and that they needed to clean it up immediately. We also told them we would be back to make sure they did. A couple weeks later, we *scheduled* a visit. I cannot stress enough that this time they *knew* we were coming. Guess what we saw on our return? Dust all over the ground. The kicker is, they had this broom and shovel out there the first time, and it was still there the second time...just leaning on the wall like 3 feet from where it was the first time. For those keeping track, that means they either a) never cleaned up the dust, or b) that they cleaned up the dust and subsequently spilled more...but either way someone had to go out there and move the shovel. So, despite us telling them that they could not do this, and that we were going to come back and make sure it was corrected, they went ahead and did actual nothing to improve the situation.I've got tons of stories like this one. People do some really dumb stuff, and then get mad when the notice of violation shows up in the mail.

#49

I actually am and OSHA Inspector but I work for a state that has their own state OSHA Plan (same as Federal OSHA but a little more strict). I can almost guarantee you that if you work construction in my state you have seen us or we have seen you. My office alone which is just one county has over 40 Compliance Officers. Yes, a lot of people hate us and yes their are some bad Compliance Officers, just like their are some bad Police Officers. When we come on site we would love nothing more than to find zero violations. The amount of paper work we have to do is astronomical. We have to treat every case as if it is going to court even though maybe only 2% do.People die at work every day from very preventable reasons. Yes, sometimes injuries and deaths are caused by employees not following company rules or taking shortcuts, but statistics also show that the companies with very good safety programs have lower accident rates and are typically very profitable.

As for worst violation that I have seen. I investigated a multiple death incident at a company. An employee entered a permit required confined space without utilizing the proper precautions. The employee became unconscious due to the inert gases that were not properly purged from the space. Another employee walks by sees the unconscious employee, tries to rescue him, that employee then became unconscious. Then again with another employee. Now they have 3 unconscious employees who eventually died from lack of oxygen.

After the investigation the company had no written confined space policy or rescue procedures. We found out after performing employee interviews that they were told to hold their breath while they performed work in the space because they were only checking a gauge and it would only take like 30 seconds.

After about $500,000 in fines and the owner actually going to jail for 5 months the company went out of business.

And the worst part is a fire department was located across the street and they were trained in confined space rescue.

#50

safety inspector for an engineering service company. the amount of basic f**kups when any floor staff tried rigging equipment to be lifted is too damn high, these people have had the correct training but seem to think "getting it done quicker" is a lot better than "getting it done safely"#51

My dad works on a large renovation project for a national landmark.He identified a hazard where workers putting up scaffolding would have to walk along the sloped incline of a plateau that functioned as the foundation for a construction shack, all the while carrying the scaffolding components.

They didn´t have to walk up the hill, or down the hill, but along the entire width of the sloped base.

This is a hazard since workers had no form of handrails/other support and could easily twist their ankles or lose their balance.

He notified the foreman about this in the morning, he didn´t think it a problem.

He notified the site manager of this in response, but he was in meetings all morning.

That afternoon, he spots a group of three guys walking on the construction site.

Shorts, sandals, and no helmets.

He walks up to them; "So gents, what are we doing? You now you need steel toed boots and helmets right?"

"Yes sir, but we're just leaving and heading home. We all twisted our ankles and can't continue working."

Sure enough, all of them had scraped/bruised knees and shins.

That were the workers putting up the scaffolding, every single one of them.

Half an hour later, the foreman comes walking over to him: "What the hell do you think you're doing, going over my head like that! I have got a schedule to finish here! Those scaffolds need to be up by tomorrow and wired by the end of the week! I don't have time for this."

"I don't know if you've noticed, but all the workers for the scaffolding have gone home injured. And now, since they can't finish the scaffolding, the electricians can't start on the wiring the day after tomorrow and the whole project is looking at a 2 weeks delay at least."

#52

We received a complaint about workers using liquid nitrogen inside of a confined space. I went out to this sand and gravel company and saw this 30' long above-ground storage tank. There was a liquid nitrogen tank outside the opening and two workers outside. I showed my ID and discovered one of the workers outside was the foreman and the other was monitoring the air quality for the workers. All good, right? Nope.The entrance was a small square opening at the end. There were about 4 workers inside the tank using liquid nitrogen to cool the tar in the tank so it could be chipped out. So, they were introducing a gas which could displace oxygen. The person doing air monitoring had a probe only a couple feet long, so it was only really checking the air quality of the fresh air mixed with tank air, NOT the air in the worker's breathing zone. The workers were about 15' into the tank.

They had no confined space training, no confined space permit, no rescue plan. The foreman then copped an attitude and told me I was wasting their time.

I red-tagged the operation (normally reserved for only when voluntary immediate compliance seems unlikely) and told them it was illegal for them to continue work or re-enter the tank until they met the confined space rules.

It was a pretty hefty fine - the company didn't appeal. I think the foreman got fired as management seemed unaware that the activity was taking place and was further upset at the foreman's reaction. Normally, sand and gravel companies in my area do a good job with health and safety - it was a rare miss for them.

#53

A powder actuated hammer is a gun that fires nails into steel using gunpowder. I once had to prevent someone from looking down the barrel of one when it jammed.Tons of fun around demolition crews too, like preventing them from demo'ing the parts of the building holding up the area they're standing on, commonly mistaking the live wires for the clearly marked out disabled wires, or constantly starting fires. When you need to work out some stress, usually they don't mind lending you a sledge hammer to go work out your frustrations on.

Anything to do with traffic around cities is a goddamn nightmare, give sympathy to the flaggers, they deserve a lot.

#54

I Work as a Fire Safety and H&S Officer, at one of my sites, this particular one being a small-medium sized shop, I was made aware of a "hidden" room. There's a narrow corridor to enter that they blocked off whenever they knew I was coming, no fire-door so any fire spreads straight onto the main shopping area.The room contains a plethora of 400/415 volt panels, and is absolutely rammed with wood, cardboard boxes, and what felt like every combustible material possible, roughly 30 years worth of c**p. Essentially, the mother of all fire hazards with enough immediate fuel and oxygen to burn down the building and neighbouring stores.

The maddening part of it was essentially all the staff at the shop were aware of it but did nothing to fix the issue and even actively worked to hide it, if you see a fire hazard please fix it or report it!

Also the sole fire escape was jammed due to the door warping and would not open at all, having not been checked in I imagine the roughly 2 months since I was last on site.

#55

Worked in a hospital lab and higher ranked coworker asked me to take inventory of things from our liquid nitrogen storage tank (-200C mind you). I asked her for the proper mitts to handle our stuff and she told me to just use our usual latex gloves. WTF.*My company rents the lab space of the hospital so I’m assuming she doesn’t know where it is and doesn’t care to ask*

I proceed to ask the hospital lab staff for proper mitts to which I was given.

After I took inventory, coworker decided she wanted to do a verification inventory check and had the audacity to ask me for the proper mitts. gtfo

Image credits: katioats

from Bored Panda https://bit.ly/3PlsnWV

via Boredpanda